crush test ect vs burst strength|ect vs mullens testing : department Store Often listed on the box maker certificate are two values, one being the Burst (Mullen) Test and the other being Edge Crush Test (ECT). Find out the difference between the two. Planes Hogar Disfruta de más de 110 canales con nuestros p.

{plog:ftitle_list}

Resultado da 4 de abr. de 2021 · 10 Dinâmicas Rápidas de Quebra Gelo. Muitas vezes, somos pegos em situações nada confortáveis que nos deixam muito .

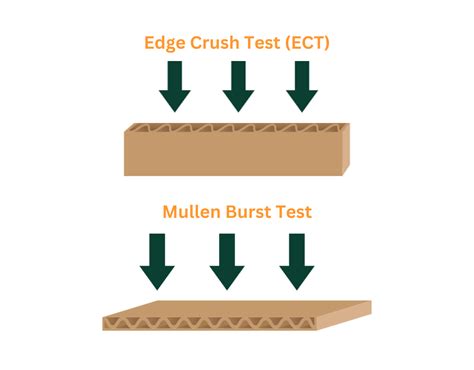

When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in pounds and is related to the handling durability of the box material.The Edge Crush Test rates how much weight can be stacked vertically on a box without damage and the Mullen Test rates how much force it takes to puncture a wall of the box. ECT rating is important to consider when stacking boxes, while .Below is a chart that breakdowns different types of corrugated material and their corresponding bursting test and ECT rating, along with the maximum load per carton. The 32 ECT, 44 ECT, . Often listed on the box maker certificate are two values, one being the Burst (Mullen) Test and the other being Edge Crush Test (ECT). Find out the difference between the two.

A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related .

This analysis aims to highlight the disparities between the Edge Crush Test and Burst Strength Test, offering guidance on when each test should be applied based on a company’s specific requirements.The fundamental difference between these two tests is that the Burst Strength Test requires a minimum basis weight of the paperboard. That is, the Burst Test requires that the base .The ECT method was developed to provide a way to determine the “strength” of a corrugated box as it relates to stacking, or Box Compression strength (also referred to as BCT or Box . Testing Corrugated Strength: Mullen Burst Test versus Edge Crush Test . If you’ve ever received a shipment that arrived in a damaged box, then you know how important it can be to get box strength right. In fact, your .

The Mullen Burst Box Strength Test measures the bursting strength of your cardboard boxes after pressure is applied. Basically, the Mullen Test determines how much pressure a box can withstand before it bursts or creates a hole. .systems. For example, while 32 ECT is an ALTERNATIVE to 200 Burst, 32 ECT is not EQUIVALENT to 200 Burst. In fact, we would expect that 200 Burst would test about 38 ECT and 32 ECT would Burst test at roughly 150. If your primary concern is crushed boxes nd stacking problems, consider specifying in terms of ECT. If it's a containment strength .Corrugated material is measured by several factors, including bursting test, edge crush test, combined weight of material, maximum weight of contents, and outer dimensions. Here is a handy chart to compare all of these variables. Please contact Pro Pac or call 888-318-0083 for your corrugated shipping cases. The Edge Crush Test, which was developed in the 1990’s, measures the stacking strength of corrugated board – how much top to bottom pressure a box can withstand before crushing. Boxes conforming to the Edge Crush Test standard are identified as 32ECT, 44 ECT, etc. Again, the higher the number, the stronger the corrugated box.

o'brien compression test

certification called ECT or Edge Crush Test. The ECT method was developed to provide a way to determine the “strength” of a corrugated box as it relates to stacking, or Box Compression strength (also referred to as BCT or Box Compression Test strength). ECT is a more appropriate measure than Burst when stacking strength is a primary design . The Mullen Test measures the bursting strength of corrugated boxes. In other words, it tests the amount of pressure or force needed to rupture the wall of the box. Boxes that pass this standard are rated with the appropriate # or lb designation – 200#, 275#, etc. The Edge Crush measures the stacking strength of corrugated boxes or the amount . 32 ECT boxes are a lightweight and cost-effective packaging option that are rated using the Edge Crush Test (ECT). The ECT measures the stacking strength of a box, which is its ability to resist crushing from external pressure. . Our 200 lb. test boxes, provide more strength and protection than 32 ect box and have 50% greater bursting .

ECT – Edge Crush Test. The Edge Crush Test (ECT) is a standardized laboratory test method that it is used to measure the cross-direction crushing of a corrugated board sample. To perform an ECT test, a force is applied perpendicularly to the specimen at a constant speed of 12.7 mm/min until it collapses.. The ECT is a true performance test and is directly related to . What is an edge crush test (ECT)? The number in a box strength measurement refers to the ECT. It tells you how much weight a corrugated sheet can withstand when standing on its edge in a lab setting. . Minimum Bursting Test (lbs per sq. inch/kg per sq. cm) . Minimum Edge Crush Test (ECT) (lbs per inch/kg per cm width) 5-10* 30* 125 * 23* 30 .03 Defining Mullen Test vs. Edge Crush Test (ECT) Page 5 04 Strength Equivalencies of Mullen Test vs. ECT Boxes Page 6 . MULLEN TEST (BURST) EDGE CRUSH TEST (ECT) 100 lb 275# ECT-48 120 lb 350# ECT-51 140 lb 400# ECT-61 160 lb 500# ECT-71 180 lb 600# ECT-82 TRIPLE WALL CORRUGATED BOXES MAX LOAD

For years the standard for corrugated packaging has been the ECT or Edge Crush Test. Edge crush slowly surpassed Mullen burst as the standard metric for corrugated strength. (Read more about ECT vs. Mullen Burst Here). The ECT value is then utilized to help calculate the “theoretical box compression strength” which is derived from the McKee .

Edge Crush Test Vs Bursting Strength Test for Corrugated Boxes. The prime reason for the popularity of corrugated packings is its cost-effectiveness and light-weightiness. Despite being lightweight, it has very strong strength characteristics. A box manufacturer stamps the boxes with a certificate that describes the quality of the box.Key Differences Between the Two Boards: Testing Method: The obvious differentiator is how the two boards are tested, using the Edge Crush Test or Mullen Burst Test. Strength: ECT boards are identified by their vertical compressive strength along the edge of the board, in pounds per inch of width (reported as ECT). Mullen boards are identified by their bursting or puncturing .The edge crush test is a laboratory test method that is used to measure the cross-direction crushing of a sample of corrugated board.It gives information on the ability of a particular board construction to resist crushing. It provides some relationship with the peak top-to-bottom compression strength of empty singlewall regular slotted containers in laboratory conditions. This changed the consistency of boxes and resulted in lower Mullen Burst Test ratings, but the vertical strength of boxes was still critical. To test this change, the Edge Crush Test was introduced. Understanding the .

Although both the Mullen Burst Test and the Edge Crush Test, which are of great significance in gauging the strength of corrugated materials, they do not measure the same properties. The ECT determines a material’s . Learn about the burst strength of corrugated boxes & the different ways to test your packaging to ensure quality & durability under different environments. . The Edge Crush Test, or ECT, measures how much force the corners and edges of a corrugated material can take until it's crushed. This is important because the corners and edges are .This was despite the fact that these ‘recycled board’ cases still had very good compression and damage resistance qualities, as evidenced in the Edge Crush Test (ECT). The Mullen Burst Test measures the force required to puncture the face of corrugated board and is reported in pounds per square inch (psi), boards are thus rated accordingly .

edge crush vs edge strength

edge crush test corrugated

Mullen Test reports burst strength in pounds, i.e., 200#. A newer standard that has achieved widespread acceptance is the Edge Crush Test. The Edge Crush Test, or ECT, is a true performance test directly related to a box's stacking strength. ECT is a measure of the edgewise compressive strength of a corrugated board.This was despite the fact that these ‘recycled board’ cases still had very good compression and damage resistance qualities, as evidenced in the Edge Crush Test (ECT). The Mullen Burst Test measures the force required to puncture the face of corrugated board and is reported in pounds per square inch (psi), boards are thus rated accordingly .a product during shipment. Bursting strength is reported in pounds (for example, A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a measure of the edgewise compressive strength of corrugated board.

Compare the Edge Crush Test and Burst Strength Test to understand their role in packaging strength and durability for effective material selection. +91 9313 140 140 . [email protected]. . Edge Crush Test (ECT): Imagine this as your cardboard's "toughness test". This ECT is an indicator of how capable a cardboard sample is in . Tests including the burst strength test, edge crush test (ECT), and others are used to determine which packaging and corrugated materials are right for your cold supply chain. Just as your products are unique, your cold supply chain is unique. How your cold chain products are manufactured, stored, packaged, shipped, delivered, and displayed .

A través de testing methods como el Edge Crush Test (ECT) y el Burst Strength Test, también conocido como Mullen Burst Test, es posible que las empresas prevean estas contingencias y diseñen embalajes protectores de acuerdo a sus necesidades. En este contexto, es común enfrentarse a la disyuntiva entre edge crush test vs burst strength.Also viewable in the seal is the Edge-Crush-Test or Burst-Test. Edge-Crush-Test (ECT) measures the stacking strength of corrugated cardboard boxes or fiberboard. Determining a finished box's compression-strength is defined by the amount of force that is needed to crush cardboard by standing it on its edge.

For comparison purposes, we include both the Mullen burst test and edge crush test (ECT) figures. The burst test represents how much pressure can be applied before the wall of a box will rupture. . (29 ECT) can hold up to 50lbs while maintaining the integrity of the boxes structure and strength. Boxes with a 200# burst rating (32 ECT) can .

box compression test pdf

Traduções em contexto de "take top" en inglês-português da Reverso Context : take it from the top, take the top.

crush test ect vs burst strength|ect vs mullens testing